Palletizer: Expertly palletized. Perfectly transported.

Pallet conveyor technology combines special expertise in steel and mechanical engineering with intelligent control technology: through a large number of parallel movements, the palletizers create homogeneous, sensitive processes to handle the packaged goods precisely during palletizing and avoid unnecessary stress.

Palletizing machines for efficient logistics processes

Palletizing machines systematically and safely stack a wide variety of packaged goods onto pallets – tailored to the specific product, desired performance, and available space. Different machine designs offer the flexibility needed for a wide range of applications in industry and logistics.

Core competence: layer palletizers

Layer palletizers combine individual packages into complete layers, which are then placed on the pallet with precise movements. The result: a particularly stable, even load – ideal for products with a uniform shape such as bags, cartons, or containers. By forming stable loading units, the palletizers for layers ensure maximum transport safety and maximum load capacity in global goods traffic.

The PLS-C series layer palletizers achieve a maximum output of 3,000 bags per hour, meeting the prevailing requirements in various industrial sectors such as fertilizers, chemicals, and petrochemicals.

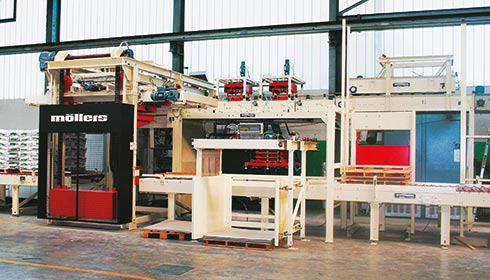

Low-level module palletizer: Palletizing at floor level

Low-level module palletizers are the compact and modular answer to limited space. Their floor-level installation allows for easy integration into existing lines without costly modifications or high superstructures. With an automated gripping system, they palletize a wide variety of products flexibly and gently. The modular design allows for customer-specific adaptations and ensures efficiency when requirements change.

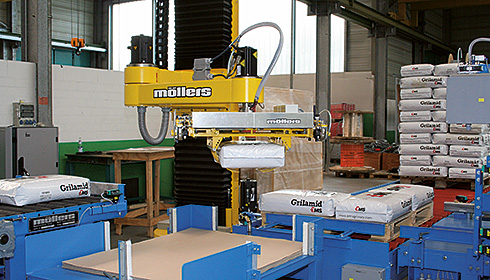

Palletizing robots: automatic palletizing at the highest level

Palletizing robots offer maximum adaptability in automated palletizing. Using a software-controlled articulated arm system, they place products or entire layers precisely on the pallet. Depending on the type of product, special gripping devices are used, such as bag, vacuum, or multiple grippers, which enable safe and gentle handling.

High-performance palletizers for optimal transport

Möllers Packaging Technology is a reliable manufacturer of palletizing machines, wrapping maschines, and solutions for the safe handling of products during transport from A to B. The use of palletizing systems requires the equipment to be highly flexible in order to efficiently form stable layers of packaged goods. Optimal pallet securing is a top priority for the provision of services to customers.

Optimal palletizing thanks to effective palletizing technology

Fully automatic palletizing systems offer companies maximum flexibility and can be switched between different product formats and pallets. This allows the systems to be seamlessly integrated into automated workflows. The machines palletize in an energy-efficient and low-noise manner and perform their tasks with high availability. One example is the articulated arm robot, which impresses with its flexible adaptation to the conditions involved in palletizing products such as bags in industrial applications.

Palletizing systems for all industries

As a manufacturer of high-quality palletizing technology headquartered in Germany, Möllers Packaging Technology has been known worldwide for over 65 years for its unmatched robustness, reliability, and high performance. The systems used meet the needs of virtually all sectors and branches of industry. Within seconds, the palletizing systems ensure that products are stacked stably and evenly. For example, bag palletizers or palletizing robots can stack and secure bags.

Advantages of our palletizing systems

-

gentle packed-material handling method

-

tailor-made solutions

-

high load security thanks to effective load stabilization

-

wide selection of palletizing systems and gripper devices