Möllers Packaging Technology: security in the food industry

When filling, palletizing and wrapping, apart from product characteristics in a hygienic environment, we also take into consideration the climatic conditions of the countries of origin – so that especially food is transported in optimal condition and in genuine food packaging.

Filling systems for the food industry

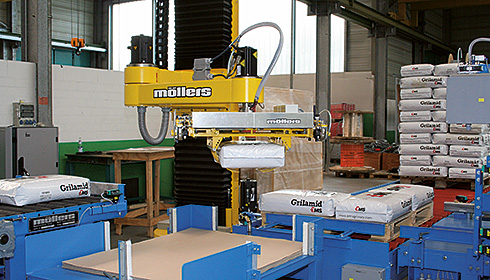

Palletizer for the food industry

Layer palletizer for the chemical and petrochemical industry (PLS-C)

The PLS-C layer palletizer combines competences from steel and mechanical engineering with intelligent control technology: up to 3000 This series meets the requirements of the fertilizer industry.

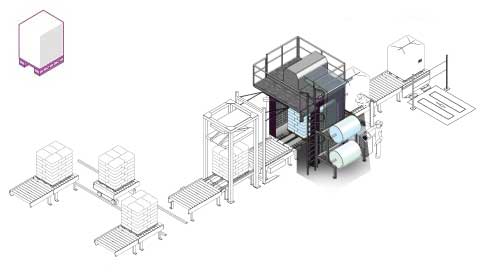

Low level palletizer PFS: attractive for special tasks

The slide plate of the low level palletizer PFS functions at floor level – for palletizing with frequent product change and capacities up to 1200 bags/hr.

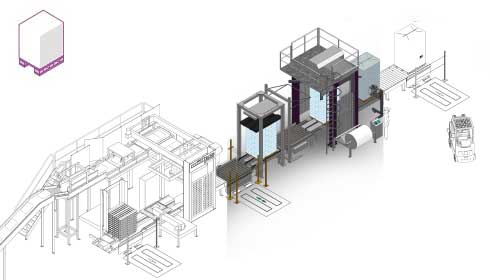

PHS: Palletizing and stretch hooding in one machine

The PHS combines as 2in1 in one machine the low level modular palletizer with an automatic stretch hooding machine.

In a confined space scenario: the ROMEO® Palletizing robot

A palletizing robot is a palletizing all-rounder – the ROMEO® demonstrates its high-precision capabilities in confined spaces in particular.

Articulated robot with gripper systems

Designed for high-performance and precise placing: the articulated-arm robot with individually developed gripper.

Wrapping machines for the food industry

Automatic stretch hood machine (HSA-Vario)

Our stretch hood machine utilizes the restoring forces of the film in order to bond pallet and load tightly and securely with each other.

HSA-Vario D

Wrapping machine with two bobbins and patented film-end ejector

Award won: palletless shipping units (PSH-1 and PSH-2)

Palletless packsare shipping unit, transport security and weather protection in one. Available: 2- or 4-Way shipping units

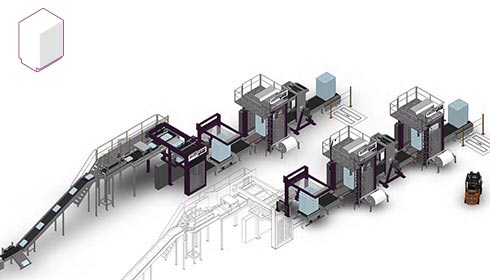

PSH-Vario: one system, three options

As a pioneer, the Möllers Packaging Technology supplies a universally functioning system which - at the touch of a button and at maximum speed - wraps packs with pallet, with slip-sheet as well as without pallet.

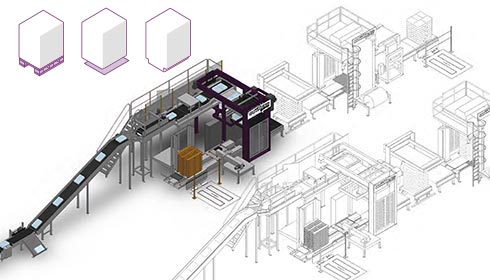

PHS: Palletizing and stretch hooding in one machine

The PHS combines as 2in1 in one machine the low level modular palletizer with an automatic stretch hooding machine.

Shrink film technology with film shrink frame (FSA)

Where goods have hardly any intrinsic stability, the FSA tubular film covering machines with separate shrink frames are recommended.

Wrap stretch-film technology: Favorably-priced load security

For lines with low capacity requirements product pallets are secrured by favorably-priced wrap stretch systems.