Perfect Match: ROMEO® palletizing robot plus gripper

Palletizing, depalletizing and picking: Tailored to all application, perfect the palletizing performance of different grippers.

The ROMEO® palletizing robot: optimum space and application utilization

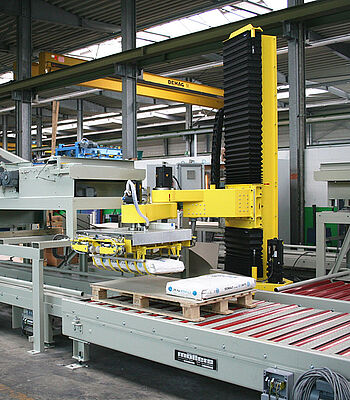

Replacing a layer palletizer, robots can be set up for a number of pack formats and layer patterns and moreover offer further features: they sort, palletize and depalletize.

The ROMEO® palletizing robot from the Möllers Group functions equally efficiently as well as economically according to the proven Scara-Principle, whose design is modeled on the human arm.

The Möllers Group presents the "smallest palletizing robot" worldwide

Perfectly adapted to the respective application, different grippers are employed. ROMEO can also be perfectly integrated into the Möllers Group wrapping lines even in confined spaces.

Technical details

Technical Data

- Payload: 50kg

- Work area (column rotation angle): 340°

- Work area-outer diameter: 3700mm*

- Work area-inner diameter: 1600mm*

- Gripper rotation angle: 340°

- Product-dependent capacities up to 1200 bags/hour independent of logistical solution task